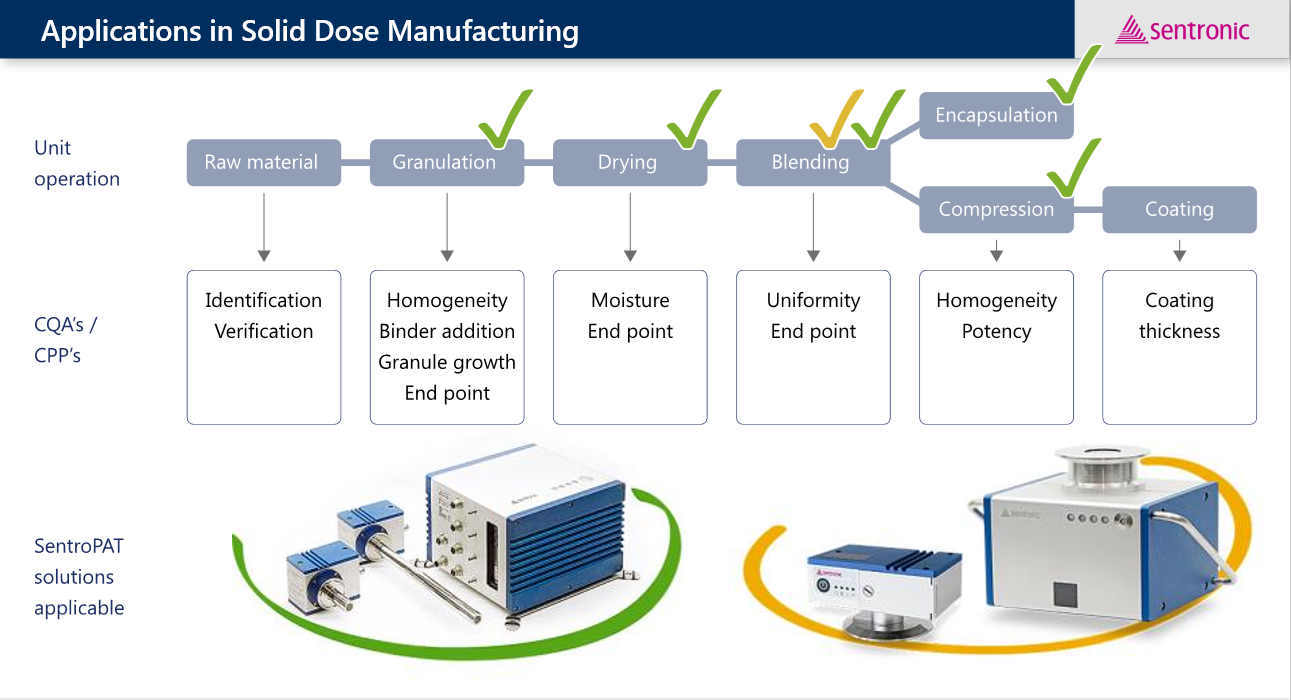

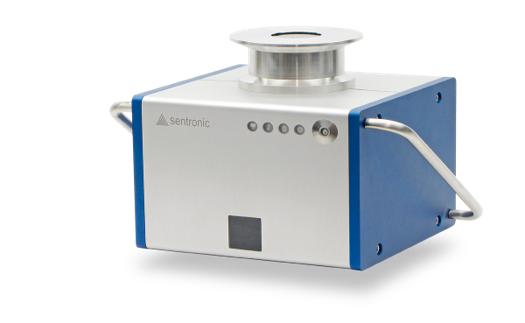

The SentroPAT BU II is a dedicated system for pharmaceutical powder blending. The system helps to understand process variability and critical quality parameters of the powder blending process. It allows to define process end point by product properties instead of « fixed time ». The system also enables real time release.

Excellent accuracy, stability and high optical resolution allow sensitive monitoring of blend quality. Transferability of calibrations allows to scale up between development, pilot plant and full production.

The smooth design of this most compact instrument provides high level of GmP compliance. All surfaces are smooth and can easily wiped.

The handling is simple and user friendly. The battery is hot swappable (power is supplied by an additional internal battery). Alternatively it can be recharged in the instrument.

Measurement can be triggered by an internal MEMS sensor, which measures analyser orientation. Alternativelly triggering based on the NIR signal is possible.

The system incorporates a low power embedded PC running Windows 10. All measured data are stored in the internal SSD and are save even at communication errors. The use of 2 internal wireless antennas improves communication stability under moving conditions.

SentroPAT BU II systems are easy to mount on a wide range of blender systems using a hygienic 4” tri-clamp connector. Sentronic provides process windows and integration support to equipment specific bin lids. Alternatively process windows can be welded into the bin wall. itself.

The system is fully validated and comes with IQ/OQ documentation. SentroSuite GmP, 21CFR part11 compliant software is installed on the system and includes automated validation routines for instrument performance.

Et plus...

| Technical Data | SentroPAT Blend Uniformity TL |

|---|---|

| Wavelength range | 1350 – 1800nm |

| Spectral resolution | >= 0.3nm (configurable), specification at 2nm |

| Wavelength accuracy | < 1nm |

| Wavelength reproducibility | < 0.1nm |

| Photometric linearity | Fulfilling USP <1119> requirements |

| Noise – High flux | < 0.3 x 10-³ AU according to USP<1119> |

| Noise – Low flux | < 1 x 10-³ AU according to USP<1119> |

| Data acquisition time | 400msec |

| Sampling interface | Non contact, through sapphire window |

| Measurement spot size | 25mm uniform beam shape for homogeneous sample illumination effective detection area 12mm diameter |

| Working distance | Depending of sapphire window (27mm at 8.5mm sapphire thickness) |

| Power supply | 2 hot swappable batteries with in total > 5hours operation External power supply for lab operation and recharging |

| Enclosure | IP65 / NEMA4, cGMP conform |

| Dimensions | 220 x 210 x 150mm (W x D x H) Width: add 80mm for handle Height: add 50mm for flange |

| Weight | 6.5Kg / 14.5lb |

| Measurement trigger | Internal software controlled 3D position measurement |

| Communications | Wireless LAN (802.11 b/g/n) |

| Software | SentroSuite GmP |

| Validation | Software integrated validation routines according USP<1119>, EP2.2.40 |

| Service port | Connections for DVI-D monitor and 3x USB |

| Mounting | 4″ hygienic flange |

Main features

- High performance spectrometer engine, easy to mount

- accurate and reliable NIR technology

- Seamless method transfer between instruments

- GmP friendly with smooth surfaces

- Superior spectroscopic performance

- Low cost of ownership

- Hot swappable battery

- No data loss at communication failure

- OPC connectivity

- SiPAT interface