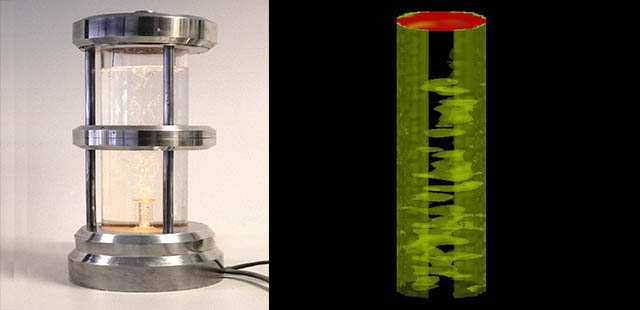

Optimisez le fonctionnement de vos colonnes à bulles pour réactions gaz-liquide grâce à la tomographie ERT industrielle. Visualisez en temps réel la distribution du gaz, analysez l’efficacité du sparger, détectez les zones gaz-riches/gaz-pauvres et pilotez votre process via des sorties de contrôle automatiques.

Solution adaptée aux procédés chimiques, organiques et milieux aqueux.

Points clés

- Tomographie ERT (ElectroResistive Tomography) pour colonnes à bulles gaz-liquide

- Visualisation et analyse temps réel de la répartition du gaz sur la hauteur et le rayon de la colonne

- Application Maxwell pour quantification précise du gas hold-up

- Adapté à milieux aqueux (ERT) et organiques (capacitance tomography)

- Détection et contrôle des performances du sparger et de la phase gaz/liquide

- Analyse statistique avancée, export contrôle 4-20mA vers systèmes automates

- Idéal pour process chimiques et industriels complexes