Supervisez, optimisez et contrôlez vos mélanges batch grâce à la tomographie industrielle ITS.

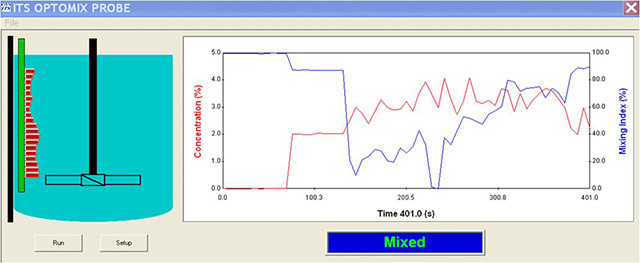

Nos capteurs fournissent des images 3D temps réel des mélanges, des mesures quantitatives précises (T90, T95) et permettent le contrôle continu de la qualité.

Idéal pour l’optimisation de cycle, le choix du mélangeur et l’amélioration des procédés, même en environnement ATEX ou milieux difficiles (suspensions, gaz-liquide, non-Newtoniens).

Points clés:

-

Surveillance tomographique 3D du mélange en batch (jusqu’à 2 400 points de mesure par capture)

-

Analyse qualitative (film du mélange) et quantitative (paramètres T90/T95)

-

Rétrofit possible : sondes, plans circulaires à électrodes, capteurs durables/anticorrosion

-

Contrôle automatique en boucle via sortie 4-20 mA

-

Adapté à tous les secteurs : chimie, pharma, énergie, gaz/liquide, systèmes complexes

-

Application idéale pour mélanges difficiles (notamment non-Newtoniens)

-

Conception robuste pour atmosphères ATEX